WPC Outdoor Decking: What Experts Won't Tell You About Installation

May 27,2025

WPC outdoor decking has changed the way we design our outdoor spaces. It brings together wood's classic appeal with unmatched durability that traditional materials can't deliver. Many experts talk about its benefits, but they often miss significant installation details that determine project success. The massive interest in DIY installation shows in the numbers - Oakio's WPC Decking tutorial has racked up 4.6 million views, proving many homeowners want to handle this project themselves.

The secret to a successful outdoor deck starts with knowing what makes WPC decking unique. Wood fibers combined with polymer composites create a weather-resistant material that stays beautiful with minimal upkeep. A proper installation technique will determine your investment's long-term performance, whether you're planning a large project with wholesale WPC outdoor decking or a simple patio upgrade. In this piece, we'll cover all the details experts usually skip to help your decking project succeed from start to finish.

What makes WPC outdoor decking different from traditional wood

The main difference between WPC outdoor decking and traditional wood comes down to what they're made of. WPC mixes recycled wood fibers (60%) with high-density polyethylene (30%) and binding additives (10%). This hybrid material works better than natural timber in several ways.

Superior Durability and Weather Resistance

WPC outdoor decking handles extreme temperatures better than regular wood. It works well from -40°C to 60°C. This impressive heat tolerance stops the deck from warping, cracking, and splitting - common problems with wood decks. The material also holds up great against moisture, which makes it perfect for humid areas or places with lots of rain.

Significantly Longer Lifespan

The biggest advantage is how long these decks last. WPC decking typically stays strong for 25-30 years with minimal care. Traditional wood decking usually needs replacement after 10-15 years because of weather damage and decay. Even though WPC costs more upfront, it's more economical over time.

Virtually Maintenance-Free

Regular wood decks just need too much work - constant staining, sealing, and sanding to look good and stay strong. WPC outdoor decking is different. You just clean it with soap and water now and then. This saves you time and money throughout the deck's life.

Environmental Benefits

Most WPC decking products use recycled materials. This cuts down on landfill waste and saves trees. To name just one example, Oakio's WPC decking uses recycled wood fibers and plastic polymers. This makes it an eco-friendly alternative to regular lumber.

Enhanced Safety Features

WPC decking comes with practical safety benefits for outdoor installation:

- Anti-slip surface texture for wet conditions

- Splinter-free surface that's barefoot-friendly

- Fire-resistant properties

Builders working on wholesale WPC outdoor decking projects get fewer replacements, lower maintenance costs, and happier clients across large installations.

Preparing for a successful WPC outdoor deck installation

Success in any WPC outdoor decking project starts with the right preparation. A full picture of the installation area will give optimal results and long-lasting performance.

Ground Preparation: Creating a Solid Foundation

Start by checking if the area is flat and stable. Clear all weeds and debris, then cover the area with root-stop fabric to stop future weed growth. Create a slight 2% slope away from nearby structures to help with drainage. This small detail is a vital part of preventing water damage and making your deck last longer.

Substructure Planning: The Hidden Support System

Your substructure needs to be sturdy, level, and clean. Space your joists based on your WPC board type:

- Square hollow decking: 300mm between centers

- Circle hollow decking: 350mm

- Solid decking: 400mm

Install double joists where two decking boards meet to prevent boards from moving or shrinking. This double-joist method becomes even more important for decks that are longer than 3.6m.

Allowing for Movement: Expansion and Ventilation

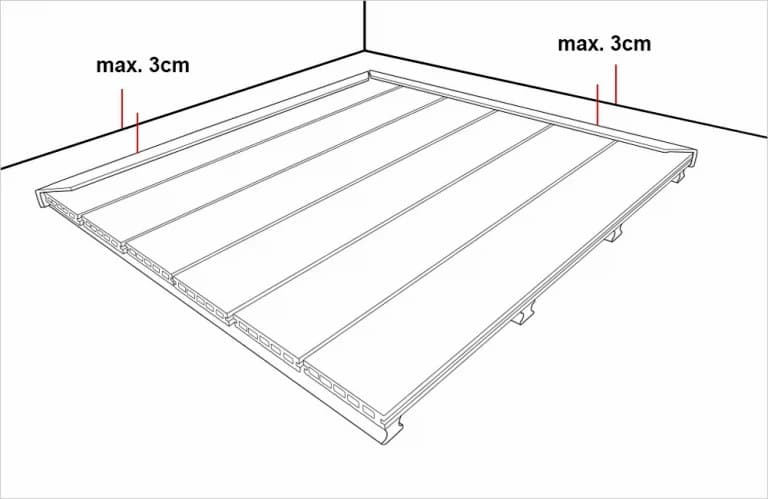

Many people overlook how WPC outdoor decking expands and contracts. Temperature changes cause the material to expand and contract by 0.3% to 0.5%. So leave appropriate gaps between boards and between the deck and nearby structures.

Your deck needs proper airflow underneath too. Leave at least 35mm of space between the deck's bottom and the base. This air circulation stops moisture from building up that could damage your deck despite WPC's improved resistance.

Check the joists' level after fixing them in place. Small shims between the joist and ground can fix any uneven spots[151]. This attention to detail will create a perfectly flat surface and stop water from pooling that could harm your WPC outdoor decking installation.

The real work of installing WPC outdoor decking starts right after you prepare the ground and gather materials. Taking your time and paying attention to detail will give you lasting results.

Installing and Securing the Joists

Space your joists properly - no more than 400mm between centers for standard installations, or 300mm where you need extra support. You'll need double joists at points where decking boards meet to stop movement and shrinkage. Larger decks need joists placed right on a concrete base, secured with expansion screws. A solid foundation requires 2-3 joist fitters per meter, with 30-40cm spacing between them.

Check each joist's level once it's in place. Small shims between the joist and ground can fix any uneven spots, which creates a flat surface and stops water from pooling later.

Laying the Decking Boards

Start with the first board using starter clips or side screws. Leave a 10mm gap from boundaries to let water drain and air flow properly. Add more boards one after another with clips or screws, and make sure the gaps stay even.

Note that WPC products expand 0.3% to 0.5%. You'll need to calculate gaps between boards based on deck length, local temperature changes, and installation temperature. Most experts recommend at least a 1mm gap.

Completing the Edges

Your edge treatment choices depend on what look you want. You can leave edges bare or add L-shaped aluminum or WPC covers. If you use WPC material for edge covering, keep that 10mm expansion gap.

Put covers over the deck edge to install them. Mark where you'll drill, make the holes, and secure everything firmly. T-clips between boards give you a smooth finish while keeping proper spacing. Board ends with exposed honeycomb structures look better with end caps, giving your WPC outdoor deck that clean, finished look.

Conclusion

I've thought about every part of WPC outdoor decking installation, and I can tell you that success comes down to knowing the details many experts skip. Without doubt, WPC material beats traditional wood decking with its durability, weather resistance, and low maintenance needs. But you'll only get these benefits if you install it the right way.

This piece gets into the key parts that make great installations stand out from average ones. The most overlooked yet crucial steps include leaving room for expansion, getting proper airflow, and building a solid, level base structure. On top of that, the exact joist spacing for your WPC board type will affect how long your deck lasts.

WPC decking costs more than wood at first, but it ended up being better value with its 25-30 year lifespan. My years of work show that most failures happen not from bad materials but because people skip the basic prep and installation steps we covered.

Take your time with preparation - it saves you trouble down the road. So, when you install your WPC deck carefully, it won't warp, crack, or split, and you'll barely need to maintain it for decades. And here's a bonus - by choosing recycled materials, you're making an environmentally smart choice for your outdoor space.

Now you know secrets that many pros won't tell you, and you're ready to build a WPC outdoor deck that will last for years to come.

PREVIOUS:

Related Posts

Are you looking for a reliable environmentally friendly composite flooring manufacturer?

We can quickly provide customers with market analysis, technical support and customized services.